Champagne:

Champagne is both a wine region and a unique method of winemaking. The wines come from the northern most vineyards in France - and the name conjures an image like no other.

An 18th Century Benedictine monk named Dom Perignon was the first to clearly document that the cold winters stopped 'still' wine fermenting, then as the climate warmed up again in spring, fermentation would start again - *(he actually didn't like the sparkling results, and while trying to stop the production of bubbles, recorded all the different influences and stages of the process which has been adapted today).

This second fermentation produced CO2 (carbon dioxide) inside the bottle, meaning the wines had a sparkle that was quite appealing. Unfortunately, the strength of this secondary fermentation frequently exploded the flimsy bottles of the day. Extra thick bottles were made in the England - and as they say the rest is history.

Champagne is typically made from 3 classic, primary grape varietals: Chardonnay and two red skinned grapes Pinot Noir and Pinot Meunier. Each play their own unique part in the dynamic, complex blend. Being a white wine crafted from predominantly red skinned grapes, is a precise and delicate process extracting the precious clear juice without skin contact.

Champagne is made to a strictly controlled process called 'Methode Champenoise'. The hand-picked grapes are first pressed and fermented to make a dry 'still' wine. The blending of all the different grape varietals and parcels to make the 'House Style' follows. Then a precise measure of sugar and yeast is added to the cuvée (blend of different grapes from the harvest year and aged, 'reserve' wines that gives its character of being a NV, non-vintage wine) and the wine is bottled and temporarily sealed with a crown cap. Then comes the 'secondary' fermentation, the CO2 that is lost to the air when making a still wines is now captured-retained inside the bottle and it bonds with the wine.

Law requires a minimum of 15 months ageing for NV 'non-vintage' Champagne. A few top houses age their wine longer to build greater complexity and depth - e.g. Pol Roger Brut Réserve NV is matured for a minimum of 3 years & Charles Heidsieck Brut Réserve NV for up to 5 years.

This process leaves a sediment in the bottle (dead yeast cells) that is extracted through a process of 'remuage' (riddling). The bottles are progressively turned and tilted upside down until all the sediment is collected in the neck. The neck is then frozen and the sediment (dead yeast) is 'disgorged' - ejected.

They fill, replace the volume of wine lost - during this phase - the winemaker may decide to add a natural sugar liqueur (dosage) to determine the final level of sweetness of the wine. Champagnes typically range from: dry, 'Brut', to slightly sweet, 'Demi-Sec'.

Levels of Sweetness in Champagne: *(grams per litre)

• EXTRA BRUT: (no dosage) also called Brut Integral, Brut Nature 0 - 6g/L

• BRUT (Dry): where the sugar content is between 6 - 12g/L

• EXTRA SEC (Off-Dry to Medium Dry): sugar content is between 12 - 17g/L

• SEC (Medium-Dry): the sugar content is between 17 - 32g/L

• DEMI-SEC (Quite Sweet): the sugar content is between 32 - 50g/L

• DOUX (Rich & Sweet): the sugar content is over 50g/L - *(no maximum)

*Doux is a style that is becoming rare, as the world is enjoying drier styles of Champagne.

Finally this complex and elegant wine is then corked, caged (muselet), rested for a few months and then labeled for each market.

NV Champagne generally does not benefit from further ageing after purchase, as the winemaker (chef de cave) has done all the hard work *(ageing in their cellars) before release, to make sure it is perfectly balanced and ready to enjoy when you buy it. But some can age, and hold well for some time - enjoy the journey.

Cuvée:

Cuvée is a wine term derived from the French word 'cuve', meaning vat or tank, though the term cuvée is used with many different meanings. On a wine label - it is used to denote a wine of a specific blend or batch. Since the use of the term cuvée for this purpose is unregulated, and most wines will have been in a tank at some stage in their production.

Please be aware that the presence of the word cuvée on a wine-label of an unknown producer, is no absolute guarantee of its superior quality. However, in the range of wines from a renowned producer who markets both regular blends and blends called 'cuvée', the cuvée-labeled wines will usually be a special blend or selected barrels of higher quality, when compared with that producer's regular wines.

Particularly terms like 'cuvée speciale', or 'tete de cuvée' (the latter especially in Sauternes AOP) should indicate a wine of very high quality and ageing potential.

Some wine producers differentiate higher-quality over ordinary cuvées as: 'reserve wines', while a cuvée lower in quality than the parent or primary wine is referred to as a 'second wine'. A cuvée wine-label may also be numbered, indicating that the winemaker has assigned a unique numbered series to that particular blend and volume.

In some wine regions, the term cuvée is used to specifically indicate a blend, i.e. a wine produced from a mixture of several grape varietals, rather than a single varietal wine. This is especially true in wine regions outside of France.

In Champagne and sometimes in other regions producing sparkling wines by; 'Methode Traditionnelle', the cuvée also refers to the best grape juice from the gentle pressing of the grapes (called the first pressing). In Champagne, the cuvée is the first 2050 litres of grape juice from 4000kg of grapes ('premier taille' - first tail), while the following 500 litres are known as the 'deuxieme taille' (second tail), and the juice due to the extra skin contact will make wines with a more coarse character and mouth-feel.

Several quality focused Champagne Houses (e.g. Charles Heidsieck, Piper Heidsieck, Pol Roger & Salon Champagne to name just a few) - pride themselves on only using the cuvée (first pressings) in their special cuvée sparkling wines.

Disgorgement:

Disgorgement is specific process of removing the dead yeast lees (sediment) resulting from the secondary fermentation which occurred inside the bottles of Champagne and other quality 'Méthode Traditionnelle' Sparkling wines.

So how is this process done? - Once the bottle has been inverted (nearly upside down - after riddling), the next process is called disgorgement, disgorging (or 'degorgement' in French), the removal of lees (dead yeast cells) now collected in the neck of the bottle. The neck containing the sediment is snap frozen by immersing it in a solution of freezing brine solution at around -20ºC to -30ºC (or with liquid nitrogen).

Once this has occurred, the bottle is carefully moved to an upward angle of approximately 45º degrees - at this point, the bottle will be closed with a bottle crown-cap in most cases, some producers may still use a cork and clip closure. Then carefully opened and the ice plug of frozen wine (containing the deposit and a small amount of wine) is ejected by the carbon dioxide gas pressure inside the bottle, leaving behind a clear Champagne.

As the wine is now very cold, there is minimum gas pressure lost from solution during this process. The bottle is then topped up with the same wine and normally sweetened with 'liqueur d'expedition' to give it the desired balance and finished style. Even wines designated as 'Brut' are sweetened and can contain 6 - 12 grams per litre of sugar.

The bottle then has the cork inserted and the wire (muselet) is applied. The sparkling wine can then rest for a period of time, and then dressed for the market and eventual enjoyment.

Until this process was invented - Champagne was cloudy, a style still seen occasionally today under the label 'Methode Ancestrale'. The removal process was a skilled manual process; modern disgorgement is now automated but still great care and attention is required to ensure the result is a clear, quality sparkling wine.

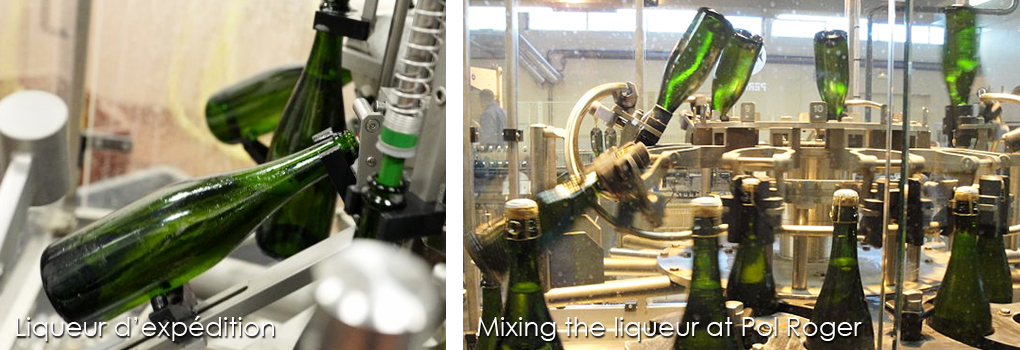

Liqueur d’expédition:

Liqueur d’expédition - a key stage in the production of Champagne & Méthode Traditionnelle wines. The addition of a sweet liquid, used to define the final level of sweetness in the finished sparkling wine. Immediately after disgorging (the removal of sediment from the bottle) but before the cork and muselet are added. The wine level is topped up, and a measured amount of a refined sugar mixture is added - (also known as dosage).

Champagne Houses used to have a mysterious recipe or mixture of ingredients in their liqueur d'expédition: including - Port wine, Cognac, elderberry wine, kirsch, framboise wine, alum solutions, tartaric acid and tannins. In days gone by, Cognac was sometimes added if the wine was low in alcohol, but this practice is now very rare.

Typically today the dosage may consist of wine, sugar (fine cane or beet sugar), brandy, ascorbic acid, citric acid, copper sulphate, plus 0.02 to 0.03 grams of sulphur dioxide as a preservative. As the sugar previously in the wine, was consumed during the secondary fermentation inside the bottle. A sweet dosage is added to balance the high natural acidity, rather than to produce a sweet taste. A ‘Brut’ style Champagne will only have a small amount of sugar added, and a ‘Nature’ or ‘Zero Dosage’ style - will have no sugar added.

After the second fermentation has completed, and the wine has spent its desired time on yeast lees, it is time for the removal of the sediment, the disgorgement. This is achieved by immersing the neck of the bottle (after riddling) in a freezing brine solution, which freezes the sediment that has gathered in the neck. The pressure of the carbon dioxide expels the frozen pellet of dead-yeast, leaving the wine clear and pristine. A small amount of liquid is lost during this process and the wine will be topped up - and the liqueur d’expedition added.

The younger the wine, or the shorter the ageing, the greater dosage of sugar required to balance its youthful acidity. High acidity is desired in Champagne as it keeps the wine fresh throughout its long period of production and also during any additional short-term cellaring by the customer. This acidity softens with age, so the older the Champagne the less dosage required. Sugar is added to nearly all Champagnes / Méthode Traditionnelle wines, because in the course of the second fermentation all the sugar is converted to alcohol and CO2, producing a dry sparkling wine that is not to everyone’s taste. There is no chance of the wine undergoing a third fermentation in the bottle with the additional sugar, as all the yeasts is expelled at the time of disgorgement.

The actual sugar content will also depend on a desired style:

• Extra Brut (0 - 6 grams/litre) = Bone dry.

• Brut (6 - 12 grams/litre, as of July 2009) = Very dry to dry.

• Extra Sec or • Extra Dry (12 - 20 grams/litre) = Dry to medium dry.

• Sec or Dry (17 - 35 grams/litre) = Medium to medium sweet.

• Demi-Sec or Rich (35 - 50 grams/litre) = Sweet.

• Doux (50+ grams/litre) = Very sweet, but this style is now extremely rare.

For the production of ‘Vintage’ and ‘Cuvées Prestige’, the liqueur d’expedition is prepared with the same wine as that disgorged. This is to ensure that the wines bouquet and character is not changed in any way. For non-vintage wines the dosage can use reserve wines from previous harvests.

Carbon dioxide can cause a reduction of one’s perception of sugar. Only the best Champagnes have the gentleness to be ‘perfectly balanced’ without any added sweetness. It can also be said that excessive sweetening conceals and helps to mask any defects in Champagne. Perhaps the best known natural (zero dosage) wine is Drappier 'Brut Nature'. Dosage also allows for minor attenuation's of a sparkling wines character. The addition of a recent vintage as part of the dosage can add freshness and brighten up the finished blend.

The amount of dosage given to each wine varies typically from 0-45ml. The remaining amount of liquid to finish with 750ml comes from sparkling wine added before the cork and muselet are added. The dosage and added sparkling wine have to at the same temperature of the bottled wines. Following dosage, cork and muselet the bottles are then shaken to distribute the dosage within the wine and rest for up to 6 months before dressing (labelling) and selling.

Muselet:

A muselet is the wire cage that fits over (and holds firmly in place) the cork of a bottle of champagne or sparkling wine to prevent the cork from ejecting under the pressure of the carbonated wine inside.

The name muselet derives its origin from the French word museler, to muzzle. The muselet often has a metal cap incorporated in the design which may show the name, logo, emblem or creative design of the producer.

Then on most occasions the muselet is normally covered by a branded metal foil envelope or capsule. Muselets are sometime also known by the name wire-hoods or Champagne wires, or cork cage.

When Champagne was first produced in the 18th century - the pressure of the sparkling wine was contained by wooden plugs wrapped in an oil-cloth and sealed with wax. As you might imagine this method proved inconsistent either from the wine leaking or blowing out of the stopper - so a method of restraining a cork using a cord was then developed.

It was in 1844 that Adolphe Jaqueson invented the more secure method of restraining the cork by using steel wire. However the early muselets designs were not easy to install and proved a little inconvenient to open. Further developments over coming years led to the modern muselet design - which is made of steel wire twisted to add extra strength and with a small loop of wire twisted into the lower ring which can be untwisted to release under control the pressure of the muselet and give access to the cork stopper.

Originally made by hand - today Muselets are now machine made in there millions. A further modern development has been the production of personalized caps within the muselet on which are displayed the colourful emblems or name of the Champagne of Sparkling wine producer. For some these may even vary in designs and artists impression used from year to year and between different manufacturers to become collector items. This has stimulated an enthusiastic market for the collection and trading of these caps and displayed the world-over.

Riddling:

Riddling is an important process and stage in the traditional method of making Champagne or quality sparkling wine that is required for 'bottle fermented' wines.

After aging the bottles undergo a process known as riddling (remuage in French). In this stage the bottles are placed on special racks called 'pupitres'. Traditional Riddling Racks consists of two rectangular wooden-boards with a hinged top.

On both sides of the wooden-racks, there are six vertically joined pieces, each row has ten holes designed to hold the Champagne bottles by its neck. The riddling rack is capable of holding 120 bottles of Champagne; however, there are some that are able to hold more. The person that places the bottles in the racks is called the riddler.

Each bottle is then marked on its base; generally with a white line. On a daily basis, the riddler must turn each bottle a few degrees. After placing each bottle at a 45 degree angle with the cork pointing down. The shake and twist is intended to dislodge particles that have clung to the glass and prevent the sediments from caking in one spot; the tilt and drop encourages the particles, assisted by gravity, to move downward towards the neck; the time in between riddling allows the particles to settle out of solution again. In about 6 to 8 weeks the position of the bottle is pointed nearly straight down with sediment in the neck of the bottle.

This manual way of riddling sparkling wine is still used for Prestige Cuvées, but has otherwise been largely abandoned because of the high labour costs. Today this process is nearly entirely done by a machine invented in Spain in the 1970's. Since they handle hundreds of bottles simultaneously, gyro-palettes are both more efficient and more consistent at consolidating sediments than the traditional hands-on process.

When riddling is finished, the sediment that is collected in the bottle neck is frozen to form a 'plug' which the next step in the process 'dégorgement' (or disgorgement, disgorging) removes. After adjusting the fill level in the bottle and setting the sweetness, it is corked, caged (muselet), rested, labelled and then shipped to different markets.